Lesser Grain Borer (Rhyzopertha dominica): Identification, Damage & Control

Among the many insects that attack stored products, the Lesser Grain Borer (Rhyzopertha dominica) is one of the most feared worldwide. Unlike secondary pests such as flour beetles or merchant grain beetles that rely on processed food or damaged kernels, the Lesser Grain Borer is a primary pest. It bores directly into whole kernels of grain, feeding and reproducing inside them.

Among the many insects that attack stored products, the Lesser Grain Borer (Rhyzopertha dominica) is one of the most feared worldwide. Unlike secondary pests such as flour beetles or merchant grain beetles that rely on processed food or damaged kernels, the Lesser Grain Borer is a primary pest. It bores directly into whole kernels of grain, feeding and reproducing inside them.

This destructive ability makes it especially dangerous for bulk storage in silos, warehouses, and shipping containers. Losses from infestations include reduced grain weight, quality degradation, and contamination. Globally, stored product pests, including the Lesser Grain Borer, contribute to billions of dollars in losses each year.

This guide will explain how to identify the Lesser Grain Borer, understand its biology, recognize infestation signs, and apply both household and professional control methods.

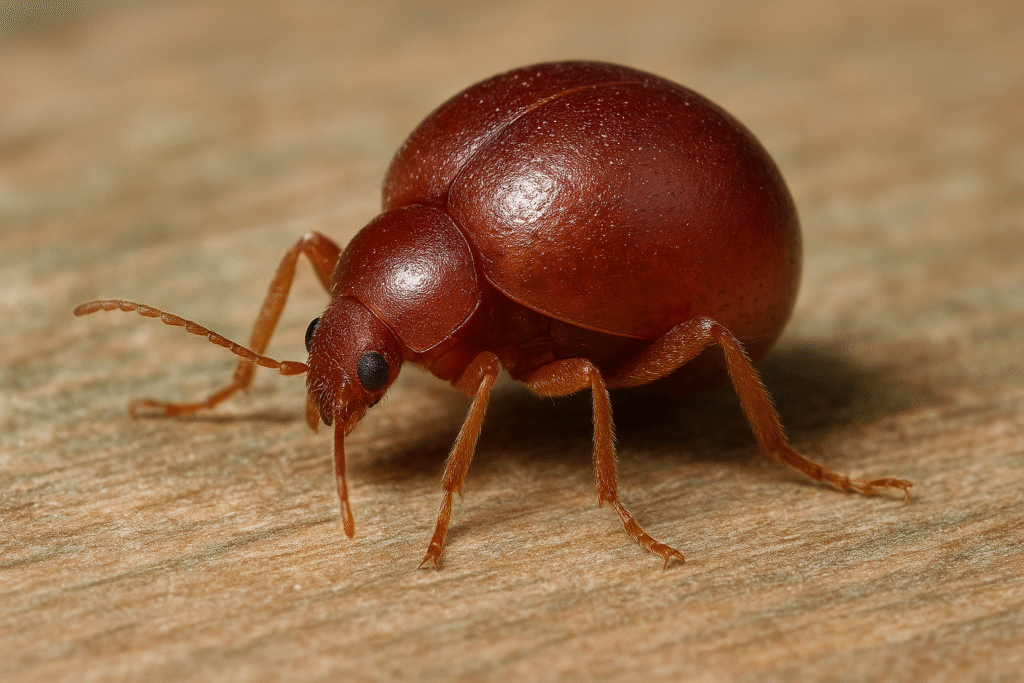

Identification

Adults:

-

Length: 2–3 mm.

-

Color: dark brown to black.

-

Shape: cylindrical body with a hood-like thorax that hides most of the head.

-

Flight: strong fliers, capable of moving between storage facilities.

-

Behavior: boring into kernels, leaving small round exit holes.

Larvae:

-

White, soft-bodied, curved grubs.

-

Found inside kernels where they feed unseen.

Eggs:

-

Tiny, white, deposited on kernels.

-

Difficult to spot without magnification.

Pupae:

-

Develop inside hollowed kernels before adult emergence.

Distinctive signs include round holes in kernels and grain dust (frass) around infested products.

Biology and Lifecycle

-

Egg laying: Females deposit 200–500 eggs during their lifespan.

-

Hatching: Eggs hatch in 4–6 days under warm conditions.

-

Larvae: Feed inside kernels for 3–6 weeks, hollowing them out.

-

Pupation: Takes place within the kernel.

-

Adults: Live for 2–3 months, though under favorable conditions can persist longer.

Reproduction conditions:

-

Optimum temperature: 30–34 °C (86–93 °F).

-

High humidity accelerates development.

-

Several generations per year in warm climates (5–6 annually).

The hidden development inside kernels makes Lesser Grain Borers particularly difficult to detect and control.

Ecology and Distribution

-

Native to South Asia but now found worldwide.

-

Especially damaging in warm climates such as Asia, Africa, Australia, and the southern United States.

-

Rare in colder climates, though infestations occur in heated storage facilities.

Risks and Damage

The economic importance of the Lesser Grain Borer cannot be overstated.

-

Direct Kernel Damage: Adults and larvae bore into whole kernels, causing weight loss and reducing nutritional value.

-

Frass Production: Infested grains show fine powdery dust, indicating advanced infestations.

-

Quality Loss: Infested grain loses grade quality, leading to rejection in trade.

-

Economic Losses: Severe infestations can reduce grain weight by 20–40%, with losses reaching billions globally.

-

Secondary Effects: Infested grains encourage mold growth and attract other pests.

Signs of Infestation

-

Small, perfectly round holes in kernels.

-

Grain dust or frass at the bottom of storage containers.

-

Hollow kernels that crumble easily when pressed.

-

Musty odor from infested grain.

-

Presence of live adults when grain is sifted.

Because larvae develop inside kernels, infestations may remain hidden until populations explode.

Household Control

Though most problems occur in commercial storage, Lesser Grain Borers can appear in households if infested grain or rice is purchased.

-

Inspection: Check rice, wheat, corn, and other grains for dust or holes.

-

Removal: Discard infested packages in sealed bags.

-

Freezing: Store grains at –18 °C for at least one week to kill all life stages.

-

Heating: Expose grains to 55–60 °C for several hours.

-

Airtight Storage: Use sealed containers to prevent spread.

Industrial and Professional Control

In large-scale storage, control is far more complex:

Sanitation:

-

Essential to remove old grain residues, dust, and cracks where adults hide.

Aeration & Temperature Management:

-

Cooling grain below 15 °C halts development.

-

Aeration systems are widely used in silos.

Fumigation:

-

Phosphine fumigation is the most common method, killing all life stages.

-

Requires licensed professionals and careful monitoring.

Modified Atmosphere Storage:

-

Reducing oxygen to <1% and raising CO₂ to >60% suffocates beetles.

-

Suitable for organic or export storage.

Insect Growth Regulators (IGRs):

-

Used in some programs to disrupt reproduction.

Integrated Pest Management (IPM):

-

Monitoring with traps, strict hygiene, temperature control, and fumigation only when necessary.

Case Study: Infestation in an Australian Wheat Silo

An Australian grain silo reported weight losses and quality downgrades. Inspection revealed Lesser Grain Borers, with round holes and frass in stored wheat.

Management applied:

-

Aeration cooling to slow reproduction.

-

Phosphine fumigation across silos.

-

Sealing cracks to reduce beetle harborage.

-

Monitoring with traps to detect early re-infestation.

Within two months, populations declined sharply, and grain quality stabilized.

FAQ

Q: Do Lesser Grain Borers attack flour?

A: No, they prefer whole kernels. Flour is more vulnerable to secondary pests.

Q: Can they fly into new storage areas?

A: Yes, they are strong fliers and spread quickly between facilities.

Q: How much grain can they destroy?

A: Severe infestations can reduce grain weight by up to 40%.

Q: Do they bite humans?

A: No, they do not bite or sting.

Q: What’s the best industrial control method?

A: Fumigation and modified atmosphere storage, combined with strict sanitation.

Final Thoughts

The Lesser Grain Borer is one of the most destructive pests of stored grain worldwide. Unlike many other pantry or warehouse beetles that need cracked kernels or processed products, this insect attacks whole grains directly, making it a primary pest and a major threat to food security.

Its hidden lifestyle inside kernels makes early detection difficult. By the time holes and frass are visible, populations are usually already high. That is why prevention and monitoring are critical. For households, airtight storage, freezing, and discarding infested products are often enough. For industry, the challenge is far greater, requiring a combination of sanitation, aeration, fumigation, and modern methods like modified atmosphere storage.

In terms of global food loss, the Lesser Grain Borer is sometimes called a “billion-dollar bug” because of the enormous cost it causes each year. But with proper Integrated Pest Management (IPM) strategies, its damage can be contained.

The takeaway is simple: whether you’re a homeowner protecting a bag of rice or a grain operator safeguarding thousands of tons of wheat, awareness and proactive measures are the only way to stay ahead of this pest.

Read more in our blog and explore guides on many other enemies. Stay informed.

Explore more Stored Product Pests

Disclaimer

This article is for informational purposes only. Pest control laws and approved chemicals vary by country. For best results and legal safety, we strongly recommend contacting a licensed pest control professional in your local area. Always make sure that the pest control technician is properly certified or licensed, depending on your country’s regulations. It’s important to confirm that they only use approved products and apply them exactly as instructed on the product label. In most places in Europe, UK, or USA, following label directions is not just best practice—it’s the law.

Author

Nasos Iliopoulos

MSc Agronomist & Certified Pest Control Expert

Scientific Director, Advance Services (Athens, Greece)

Licensed Pest Control Business – Ministry of Rural Development & Food (GR)

References

-

Wikipedia – Rhyzopertha

-

Purdue University – Stored product pests